Vacuum Conveying Systems: What They Are and Why You Need Them

The incorporation of more automated systems into a factory’s distribution channel cannot be overemphasized as it readily facilitates and allows for a more seamless running of operations.

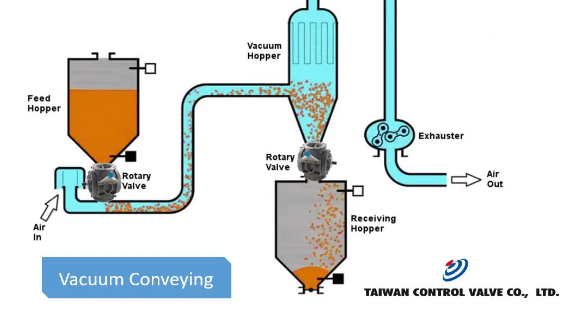

A vacuum conveyor is one of these systems and with these, more dry materials can be transported across different locations in factories in bulk quantities. This is possible through the incorporation of suction alongside a brush-type motor that allows the dry materials to be pulled through the system. With the suction, a partial vacuum is created within the Feed Hooper which allows air to be expelled from the system, forcing the dry material to be transported through the tubes to the desired point.

If you run an agricultural, plastics, grains, coffee and tea, dairy, or other dry ingredients industry on a large scale, then you would most certainly need a vacuum conveying system.

Here’s how the conveying system would serve you:

Table of Contents

Why You Need Vacuum Conveying Systems

Fast and Reliable

When it comes to bulk transfer of materials, it is normal to find operating managers in search of easier and faster ways to get the job done. This is one specific feature that a vacuum conveying system offers.

Vacuum conveying systems are very gentle on the materials and, as such, even while they transfer the materials from suction to the desired point with increased speed, a guarantee that separation of the material blends during the transfer is assured. In addition to speed, vacuum conveying systems also ensure that the quality of materials transferred is not compromised.

Minimizes Health and Environmental Hazards

One peculiar thing about transporting dry materials, particularly powder, is the characteristic dust they typically fan-out, which not only affects your health and the environment but is also a potential source of ignition in the factory.

With a vacuum conveying system, however, this dust is one less thing to worry about as dry materials are now transported in a more contained manner.

Environmentally Friendly

A major way to minimize factory energy expenses is to incorporate the use of vacuum conveying systems. This is because vacuum conveying systems are highly energy efficient as they operate on energy-conservative Multijector vacuum pumps. This self-contained vacuum conveying is a typical example.

Even under hazardous conditions, it is possible to operate your vacuum conveying system 100% by air without its speed or efficiency being compromised. The vacuum conveying system has also been cGMP verified confirming the proper design and hygienic manufacturing processes of the vacuum conveyor.

They are Very Easy to Install and Use.

Most of us get worried about complexity when it comes to using systems like the vacuum conveyor. The design of the vacuum conveying system, however, facilitates ease.

Not only is the mode of operation easy to use, but the installation and control of the system are simple to understand and can be carried out swiftly.

Vacuum conveying systems are one of the few conveyors used in factories that require the least amount of cleaning and maintenance. Vacuum conveying systems are sure to up level your factory’s distribution methods of dry materials, particularly bulk description.

For more valuable information visit the website